If you are looking for that one line ca make various pastries , no matter it is Puff pastry, Danish pastry, palmier, Pastry swril, and so on, here is your choice

Order(MOQ) :

1 linePayment :

T/T; L/CProduct Origin :

ChinaShipping Port :

Shanghai portLead Time :

90 days

• Line description

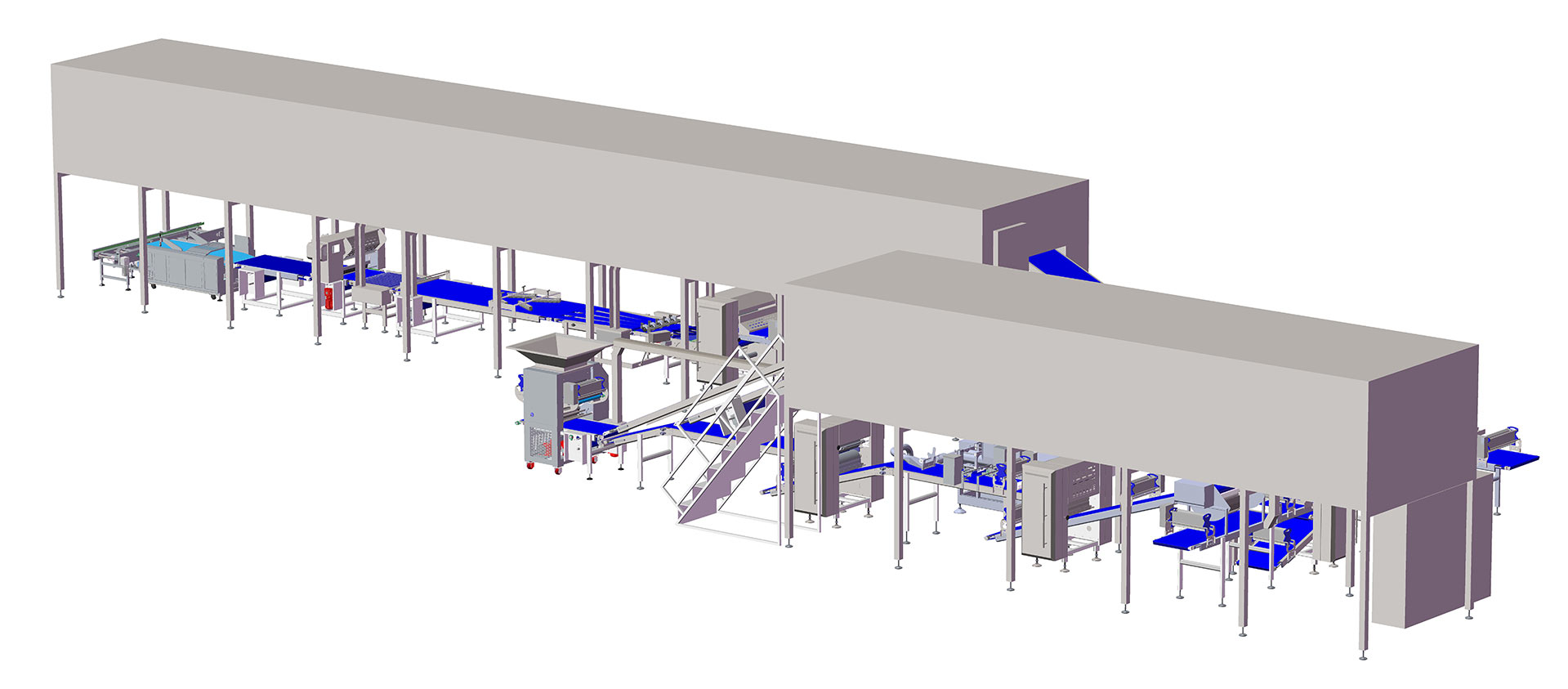

Pastry production line is mainly for making baked products which have a flaky or crumby texture. Because of its modular design, Danish pastry, puff pastry, palmier, pastry swirl, and frozen laminated dough, ect, are easy to be produced on the same line by adjusting the related mechanism.

To satisfy the filled products’ production, ZLINE can supply various filling system which is suitable for ingredients in liquid, soft, particles, viscous.

The line is equipped with2 sets of freezers to be used when production processing needed. Freezer’s temperature is adjustable. Position of the freezer can be above the line or on the grand.

• Targeted products

ZLINE can customized the forming tools just based on your pastry shape to make this line is flexible enough to produce kinds fo Danish pastry or Puff pastry.

• Line configuration option

Based on different capacity demand, ZLINE has the pastry sheet production line in output dough width of :

600mm , 800mm, 1000mm, 1200mm, 1300mm, ect.

Also, this line can be equippmend with online proofing system, tunnel oven and automatic packing system to satisfy food factory's demand of mass and high automation industrial production.

• Line work flow

Dough hopper& extruder - Freezer - Calibrator - Fat pump - Butter feeding& folding unit - Satellite - Laminator - Satellite – Guillotine - Retractable laminator - Satellite- Quick freezer - Satellite - Satellite - Cross sheeter - Calibrator - Calibrator - Flour sweeper - Dough strips divider - Dough strips separating unit - Forming table - Dough strips closing unit - Guillotine - Panning machine

• Technical parameters

| Line model | ZKSD-600 |

| Line layout method | U-shape |

| Dimension (L*W*H) | L33.0m*W9.5m*H2.4m |

| Belt width | 650mm |

| Dough width | 600mm |

| Dough thickness | 2mm-30mm |

| Energy consumption | 105KW/380V,50HZ, 3PH ( supplied as demand) |

| Total weight | 53000 KG |

| The number of butter layers | ≤49 |

| Butter/margarine : dough | 1:1 - 1:10 |

| Height of dough hopper | 2100mm |

| Production capacity | ≤ 1500-2000kg/h |

• What is the function of 2 online coolers?

This line is mainly used for the production of Danish products. The production line is equipped with two sets of cooler warehouses, which can adapt to the dough forming with different water contents, and at the same time relax the dough with low temperature, which can effectively improve the product quality. The belt conveyor is used in the cooler, and the cold air is directly transported to the middle of the belt, which can effectively reduce the air drying of the cold air on the surface of the skin.

First cooler is cool down the dough after dough mixer; Second cooler is to cool down the dough with butter/margarine for easy shaping, especially when you produce croissants and Danish pastries. The temperature inside the cooler tank can be ≥-28℃, adjustable.

• Why choose this line

1. Equipped with 2 sets of freezers which can be placed over the line or on the ground.

2. Rest the dough band in a low temperature to improve the final product quality.

3. Belt conveyor is adopted inside the freezer which cold wind is transported to the middle position of the belt to reduce the air-drying of dough band surface.

4. The butter tier quality of final product is improved a lot by 2 different folding units.

5. Various products can be produced on the same line by configured ideal forming cutters.

6. Automatic panning system improves the production efficiency and saves the labor cost.

7. The production line is equipped with video monitoring equipment, which can more conveniently observe the operation of the equipment at each key stage.

8. The equipment has a remote control system, which can observe the abnormal data of the equipment and remote optimization in the background.

9. The equipment has the function of automatically adjusting the thickness, and can realize the one-click switching of a variety of products by saving the formula.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)