When people talk about pastry production lines, the focus often goes to mixers, laminators, or ovens—the equipment that seems to take center stage. Yet behind the scenes, there is another machine that quietly ensures everything runs smoothly: the extruder.

|

|

|

|

The real strength of an extruder lies in its ability to guarantee consistency. By pressing doughs or fillings through precision-engineered dies, it ensures every piece has the same size, weight, and structure. In large-scale industrial baking, where thousands of products are produced every hour, this kind of uniformity is not just a benefit but an absolute requirement. At the same time, the extruder is highly versatile. It can handle sticky, high-fat doughs that are difficult to process manually, as well as smooth creams, nut pastes, or fruit fillings. This flexibility allows bakeries to expand their product range without changing the entire line, making it a practical and future-proof investment.

Another key advantage is efficiency. By automating the portioning and shaping process, the extruder reduces raw material loss, lowers labor demand, and keeps production flow stable. For bakeries aiming to grow, this means higher capacity and lower costs per unit. What makes it even more valuable is its ability to support creativity. With a simple die or nozzle change, the same machine can produce new shapes, layered textures, or filled designs. This balance of efficiency and innovation allows bakeries to compete in an increasingly demanding market.

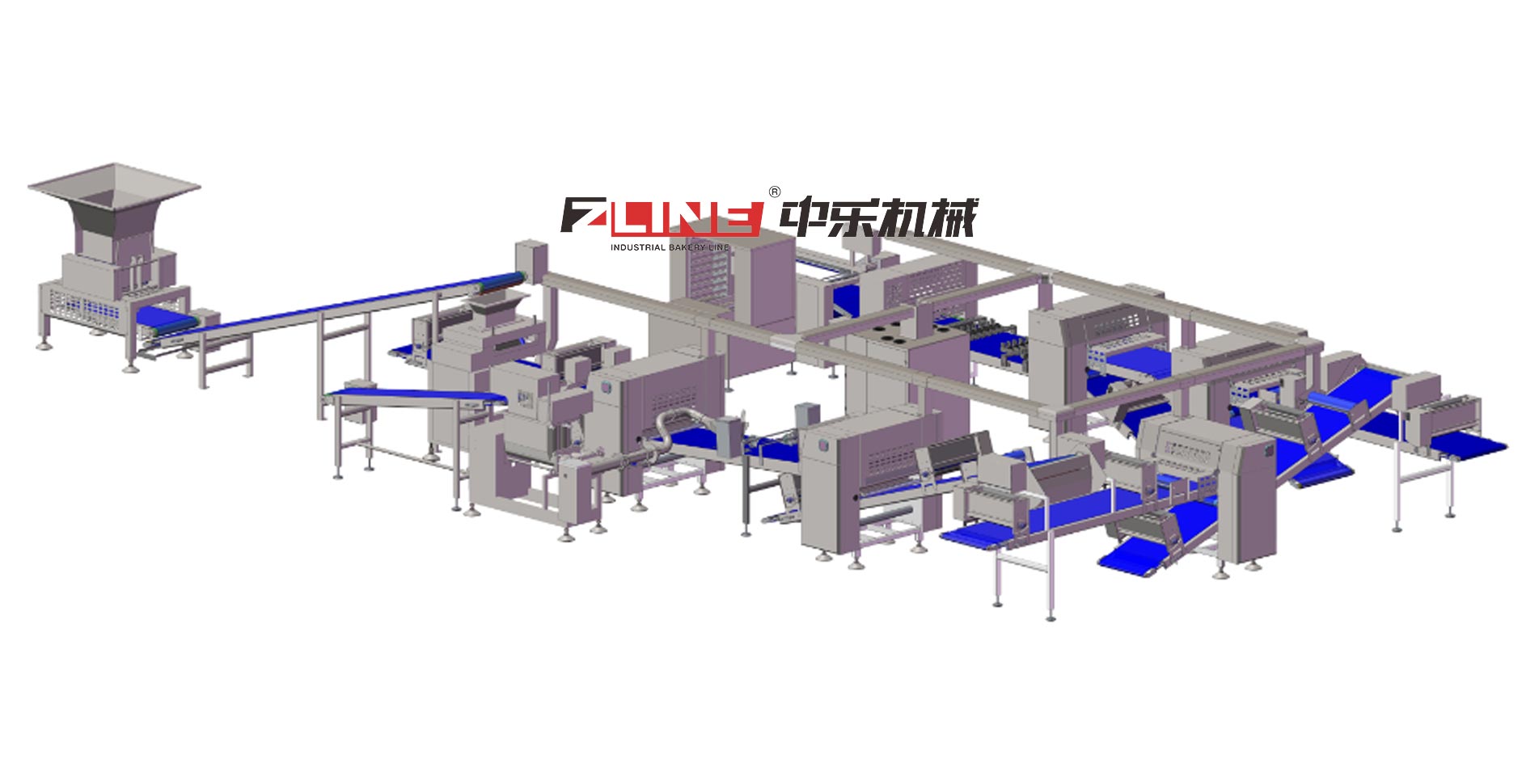

The extruder also plays a vital role in a fully automated production line. It integrates seamlessly with sheeters, cutters, ovens and other equipment, ensuring that the entire process runs smoothly from start to finish. By minimizing downtime and preventing bottlenecks, it contributes to consistent product quality and overall production stability.

At ZLINE, we design dough extruders that meet the needs of modern bakeries. Built with food-grade SUS304 stainless steel, our machines are strong, hygienic, and easy to maintain. Precision servo control guarantees accurate portioning, even with sticky doughs or complex fillings, while the full line’s capacity options ranging from 300 to 1000 kg/h make them suitable for both medium-sized factories and large-scale central kitchens. With a modular design, die changes are quick and simple, allowing bakers to switch between different products with minimal downtime.

The dough extruder may not attract as much attention as other machines, but it is one of the most important. By combining consistency, versatility, efficiency, and creative potential—and with ZLINE’s engineering expertise behind it—it enables bakeries to deliver reliable quality at scale while continuing to explore new product possibilities.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)