Before you understand the complex world of pastry, you have to understand what is laminated dough.

The lamination process involves putting large pieces of butter/margarine into the dough. The most common types of treats that utilize a laminated dough style include croissants, danishes, phyllo, and strudel.

This process is very methodical and showcases a pastry chef's ability to fold, rotate, and chill the dough. Meanwhile, it also has strict requirements of automatic production line fro industrial pastry production.

A full automatic pastry laminating line requires enough spaces and more investment budget, so it is not a small project which needs you to find a good bakery equipment supplier.

Who can supply the premium and most cost-effective pastry equipment ?

Anhui Zline Bakery Machinery Co., Ltd. began to study the pastry production line in 2010, and the first set of pastry production line was put into market use in 2013.

• Technical principle

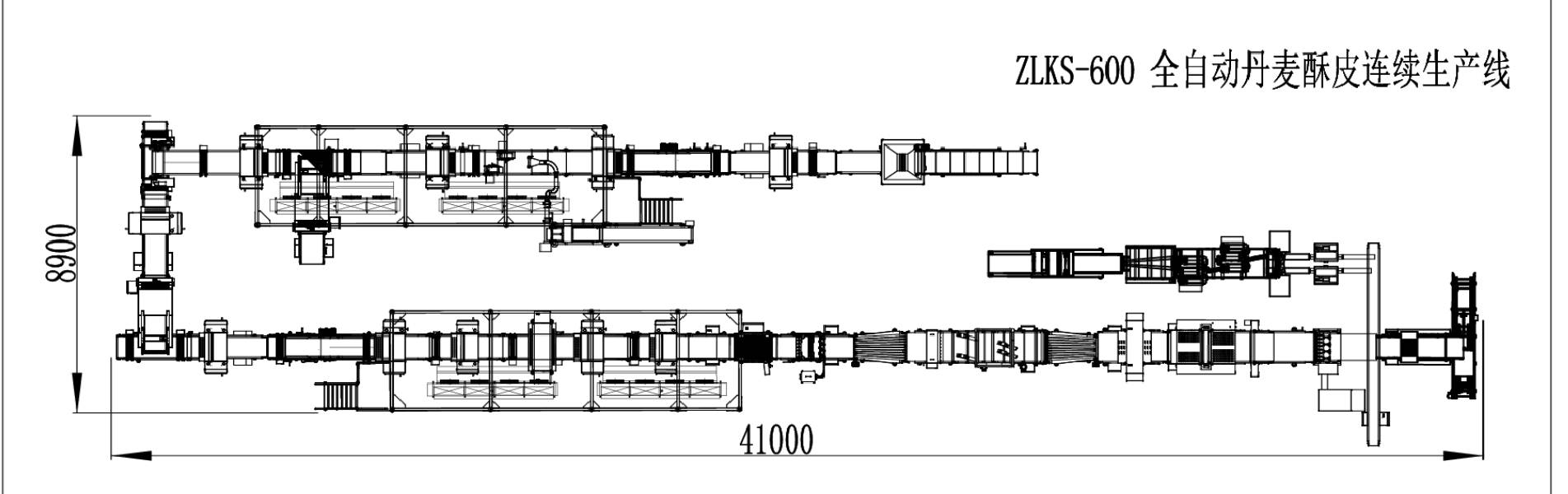

From 2013 to 2024, after 11 years of research, The pastry production line has experienced ZLKS-380 series --ZLKS-380-2 series --ZLKS-QX-600/800 series --ZLKS-600/800 series; The types of rollers has been changed from plastic roller, hollow steel roller to today's solid steel roller, ZLINE has accumulated rich market experience and trained a professional service team. The fourth generation of ZLKS-600/800 series production line adopts the advanced design principle, and combines Chinese pastry with Western Danish design in the making-up line. ZLKS-600/800 series production line has the characteristics of flexibility and product diversification.

• Equipment manufacturing

ZLINE Machinery is committed to building high-end and premium production lines for customers, providing customers with efficient, convenient and safe technical services.

The whole line of ZLKS-800 series production line adopts independent processing. ZLINE has invested 20 million yuan to purchase foreign advanced processing equipment. Totally has 32 sets of CNC machining equipment, 6 sets of Japan Mazak four-axis machining center, 11 sets of CNC turning and milling integrated machining center, 2 sets of Sodick slow wire cutting in Japan (cutting accuracy can reach 0.001mm, mainly used for precision machining of high-speed moving plates), 2 sets of laser cutting machining centers.

All the plates and pipes of ZLINE are cut by laser, with high precision and beautiful appearance, and at the same time, tailor welding adopts the traditional Chinese mortise and tenon structure design, which is easy to weld and has high strength.

In terms of appearance treatment, sandblasting treatment is adopted, and the appearance reflectivity is low, which can reduce the reflectivity of the sheet metal of the equipment and reduce the risk of eye fatigue caused by the operation of the equipment for a long time.

• Technical team

ZLINE has a total of 25 product design engineers, 5 electrical automation engineers, 5 institutional technologists, 2 product technologists, more than 30 invention patents, 3 provincial major equipment awards, and a national high-tech enterprise. Zhongle technical team has rich experience in the industry, the main customers in the circulation industry are Panpan Group, Dalimei Bachen who focus on short-term product, Taoli, Chinese pastries Luxihe, Zhan Ji, quick-frozen Intercontinental, Likunlou and other customers, we can provide customers with whole plant solutions.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)