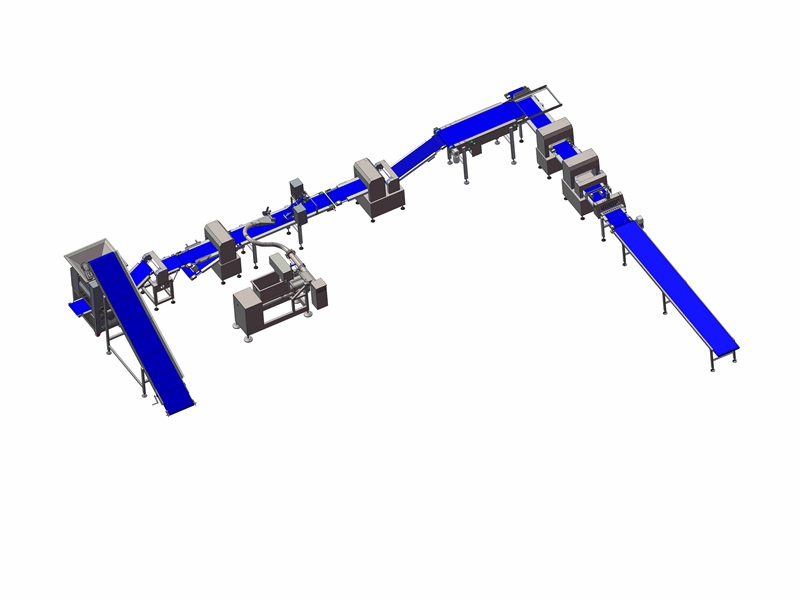

This line is producing pastry dough.

Order(MOQ) :

1 linePayment :

T/T; L/CProduct Origin :

ChinaShipping Port :

Shanghai portLead Time :

60 days

• LINE INTRODUCTION

This ine is produced dough for pastry, Danish pastry, croissants, palmier and so on.

Compared with the pastry dough laminating line of ZLKS-600, it is with less production output and less investment budget. The percentage of dough and oil, folding level can be adjusted according to customer needs. The production line meets european standards with highly configured, which can meet the demand for high output and industrial production. You can contact us at any time and we can customize it according to your needs.

• TARGETED PRODUCTS

|

|

|

|

| Butterfly crisp | Croissant | Bread | Pineapple cake |

• EQUIPMENT DETAILS

Satellite

The dough enters through this Machine set with a larger gap for an initial reduction. It then sequentially passes through subsequent roller pairs with progressively smaller gaps. Each pass gently and evenly sheets the dough thinner, further elongating and creating those distinct, delicate layers of butter and dough without tearing the gluten or smearing the butter.

Folding: for the 500 series, the number of folding layers in one fold is ≤ 7. A cutter can be configured, and all folding operations are controlled by servo motors.

|

• Reduce labor costs.

• Modular design and flexible equipment configuration.

• Famous electrical components and stable working performance.

• TECHNICAL PARAMETERS

| Line model | ZLBY-500 |

| Line layout method | U-shape |

| Dimension (L*W*H) | L15.0m*W11.0m*H2.5m |

| Roll width | 500mm |

| Dough width | 500mm |

| Dough: Butter | 1:2-1:12 |

| Power | 18KW |

| Butter/margarine : dough | 1:1 - 1:10 |

| Production capacity | 1.2t/h |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)