Lavash is a kind of popular bread in the world. We offer a wide variety of equipment that adapts to your needs.

Order(MOQ) :

1 linePayment :

T/T; L/CProduct Origin :

ChinaShipping Port :

Shanghai portLead Time :

60 days• Line Introduction

The production line is specifically designed for the automated production of Lavash, a traditional thin flatbread popular in the Middle East and Central Asia. With this production line, bakery factories can efficiently replicate the traditional lavash-making process on an industrial scale, ensuring consistent quality and high output. With a smart control system, the production capacity is adjustable, helping to reduce labor costs.

| equipment of full line |

• Line Features

1. Flexible Dough Handling System

Capable of processing both soft and semi-firm dough types, ensuring consistent sheet quality and thickness.

2. Automatic Dough Divider & Rounder

Accurately divides the dough into uniform portions to ensure consistent product weight and shape.

3. Precision Sheeting & Thickness Control

Equipped with adjustable multi-stage sheeters to roll dough to ultra-thin layers, ideal for traditional lavash.

4. Conveyorized Baking Tunnel

Continuous baking tunnel with adjustable temperature zones to ensure even cooking, slight browning, and authentic texture.

5. Intelligent Temperature & Speed Control

PLC system enables precise adjustment of baking time, sheeting speed, and conveyor timing, allowing recipe flexibility.

6. Cooling & Stacking Unit

Integrated cooling section prevents condensation and curling. Automated stacking or rolling system supports packaging preparation.

7. Hygienic & Modular Design

Made of food-grade stainless steel with easy-to-clean surfaces; modular layout allows for quick changeovers and maintenance.

8. Customizable Layout

Production line can be tailored to your desired output (pieces/hour), product size (diameter/length), and available factory space.

• Typical Production Flow

The flour, water, oil, and other ingredients are combined in an industrial mixer to form a uniform, non-fermented dough. The mixing process ensures proper hydration and gluten development for optimal dough elasticity and handling.

The dough is automatically divided into precise portions using a volumetric or weight-based divider. This step ensures that each dough ball has consistent weight and size, which is critical for uniform product dimensions.

Each dough portion is flattened into a round, thin disc using a sheeter or a heated press. Thickness and diameter can be adjusted according to product requirements (e.g., tortilla, roti, chapati). This stage defines the final shape and thickness of the flatbread.

The flattened dough is transferred to a baking section—typically a multi-zone tunnel oven or a steel belt grill—for high-temperature baking. This step rapidly cooks the dough, creating light browning and developing flavor and texture without fermentation.

After baking, the flatbreads pass through a cooling conveyor system. Controlled cooling is essential to prevent condensation, preserve softness, and prepare the product for packaging.

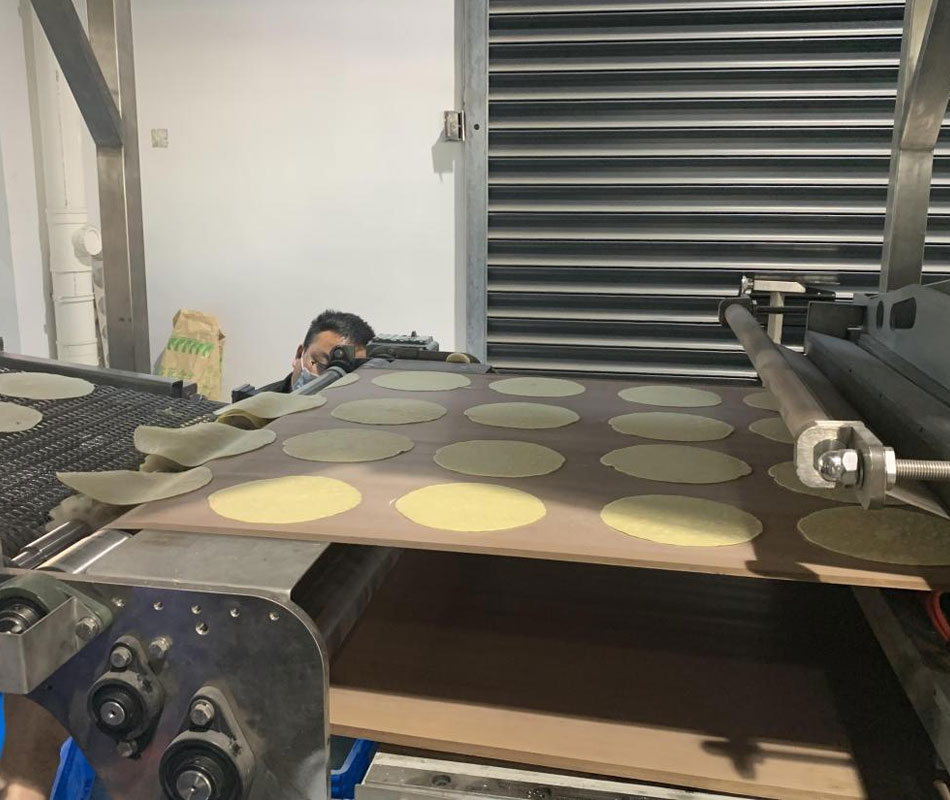

• Line Display

|

|

|

Dividing and rounding |

Sheeting |

Cooling |

• Targeted Products

|

|

|

• Technical Parameters

|

Item |

Specifications |

|

Size/Diameter |

15cm; 20cm;25cm;30cm;33cm;35cm |

|

Capacity |

3600 ~ 14400 pcs/hr (base on the tortilla size) |

|

Belt width |

1100mm/can be customized |

|

Press size |

90*90cm /110*110cm |

|

Proofing time |

12~20 min, adjustable |

|

Tunnel oven |

3 layers oven |

|

Cooling |

Natural cooling/can be customized |

|

Stacking |

Automatic |

|

Line size |

35m(L)*3m(W)*3.9m(H) |

|

target product size |

6", 8", 10", 12"…… |

|

Energy consumption |

380V, 50HZ, 3PH |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)