This chiffon cake batter aerator machine will fit for you who need little production volume, such as small business or bakery.

Item No :

ZLMDQF-180Order(MOQ) :

1 setPayment :

T/T; L/CProduct Origin :

ChinaShipping Port :

Any port of ChinaLead Time :

45daysWeight :

1000KG |

• Machine introduction

This machine is designed for producing different types of chiffon cakes and sponge cakes. It is fully automatic with high configuration, adopting the advanced Siemens control system to manage formulas and product seffectively. It is a good choice for small-capacity enterprises or bakeries, which can output high-quality egg mixtures.

The entire system consists of mixing, storage, whipping, conveying, cooling, and control systems. The continuous whipping technology enables the egg mixtures to be blended in a short time. The automatic feeding equipment conveys the egg mixtures to the cake forming machine, ensuring that the egg mixtures have the same specific gravity during production, resulting in cakes with a more uniform, stable, and attractive appearance, as well as an excellent taste.

• Process flow

| Egg White Premixing Tank→Rotor pump→Storage tank→Screw pump→Filter→Aeration head |

| Egg Yolk Premixing Tank→Rotor pump→Storage tank→Screw pump |

| ⇒Screw pump→Grouting machine→Tunnel stove |

• Technical parameters

| Machine model | ZLMDQF-180 |

| Power | 15KW |

| Voltage | 380V, 50HZ, 3PH ( Can be spplied as production area request) |

| Albumen Capacity | 30-80kg/hr |

| Yolk Capacity | 50-200kg/hr |

| Specific gravity | 0.3g/ml |

| The volume of mixing tank | 50L |

| The volume of storage tank | 60L |

| Cooling mode | Chill water cooling |

| Machine dimension | 2100mm *1650mm *1625mm (L*W*H) |

| Machine weight | ≈1000KG |

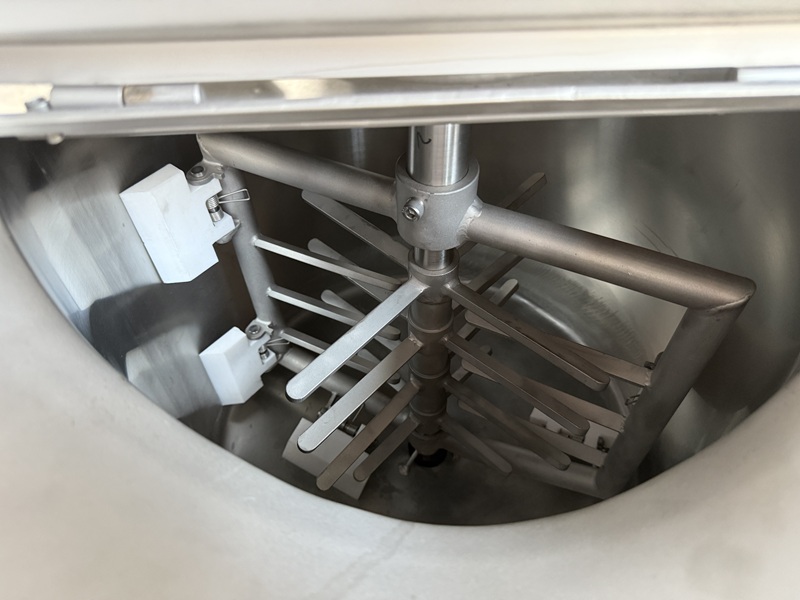

• Equipment details

|

This intelligent control system includes functions for monitoring, recipe configuration, parameter setting, manual operation, and alarm management.It is monitoring of all production parameters, adjust critical parameters, the flow of raw material pump and one-touch operation for system to start up; the recipe configuration can save and retrieve customized recipes with pre-set parameters for mixing and aeration processes; the parameter settings is mainly for the setting of all aeration parameters and the start and stop of the storage motor during aeration production ; manual control is for controlling over individual system components (start/stop);and the threshold values of some parameters are set, the alarm management system will issue an alarm and shutdown when the threshold values set for these parameters are exceeded to ensure equipment safety and operational reliability.

|

The egg yolk mixing cylinder begins to stir the materials, and the materials are put into turn according to the process flow, the order of the materials in each pot must be consistent, and the time of opening and closing the circulating pump in each pot must also be consistent; in order to ensure that the deviation of the specific gravity of the material stirred out of each pot is very small; the time to turn on the circulating pump must be under the condition that the dry material in the cylinder is completely stirred, otherwise it is easy to cause the circulating pump to freeze.

• Equipment advantages

The equipment is small, easy to move, and occupies a small area;

It adopts international advanced technology, high-end configuration, and stable performance;

The chiffon cake slurry has produced with stable density, delicate and smooth, and good taste.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)